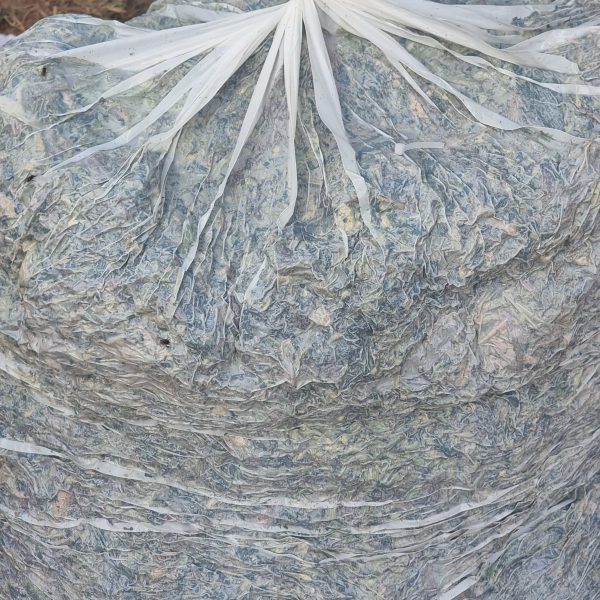

Corn Silage — What We Do & How We Do It

Corn silage Pakistan: Babar Aziz Balers supplies premium vacuum-sealed corn silage in 40–50 kg bags across Pakistan. Our silage is finely chopped and moisture-tested (target ~60–65%), then vacuum-packed with double protection for safe transport and long storage. As a result, farms get a consistent, ready-to-feed product that reduces spoilage and eases handling.

Key benefits

-

-

Ready-to-feed, vacuum-sealed corn silage in 40–50 kg bags

-

Sealed silage stays fresh for 12–18 months

-

Easy to handle and store – no forklift required

-

Consistent nutrition with reduced spoilage risk

-

Nationwide delivery and complete buyer support

-

Customer-reported milk yield improvements of up to ~25% (results vary)

Typical Nutritional Values:

-

Moisture: 65–70%

-

Dry Matter: 30–35%

-

Crude Protein: 7–9% (depending on dry matter)

-

Total Digestible Nutrients (TDN): 65–72%

-

Net Energy for Lactation (NEL): 1.4–1.6 Mcal/kg DM

-

Neutral Detergent Fiber (NDF): 40–50%

-

Acid Detergent Fiber (ADF): 25–30%

-

Starch Content: 25–35% of DM

-

pH Level: 3.8–4.2

-

-

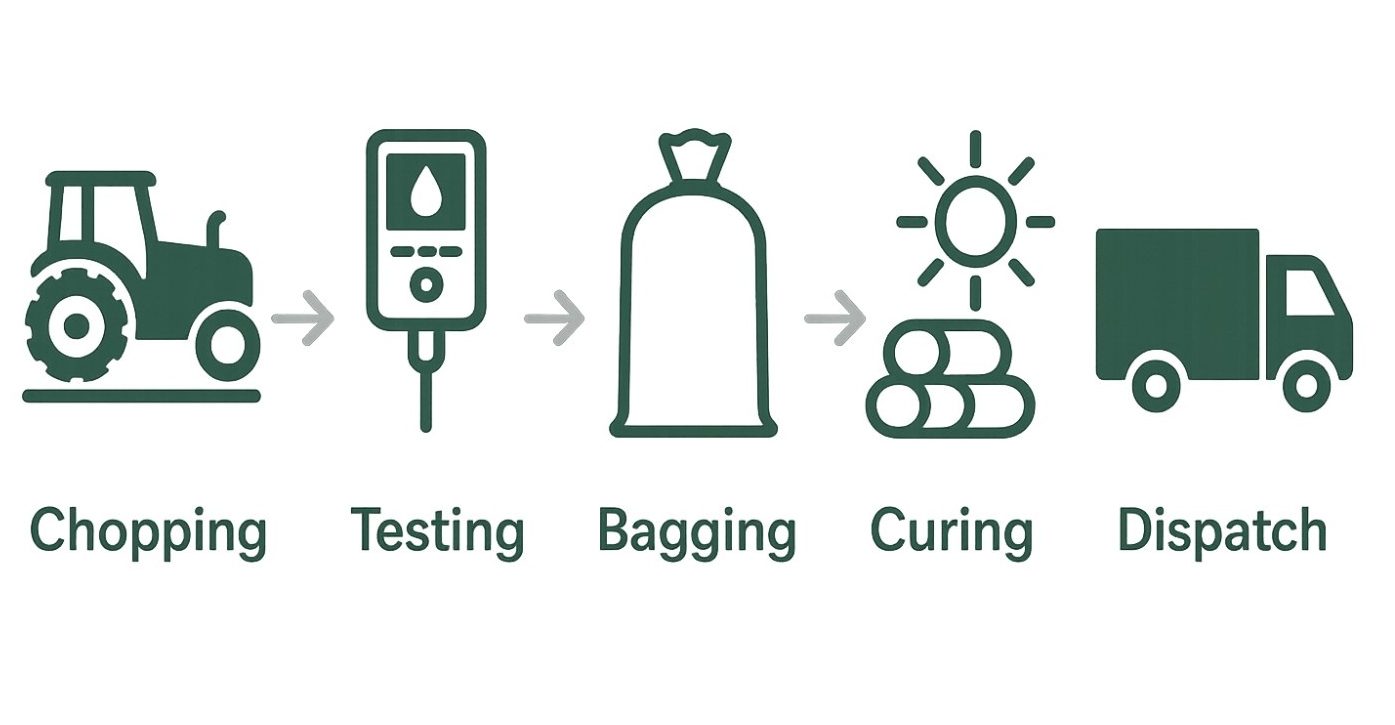

Our step-by-step process

1) Sourcing & intake

We purchase maize by acre from contracted growers or spot sellers and transport the crop to our facility for processing.

On arrival we inspect color, kernel abundance and general quality, and take random field/lot samples to confirm readiness. We also rely on local harvest knowledge — when farmers in an area planted and typical maturity times — to help schedule harvests.

2) Harvest readiness checks

In Pakistan there are two common harvest methods. Hand-cutting often gives higher usable yield because labour cuts close to the ground; consequently, less crop is wasted. By contrast, mechanical harvesters work faster but typically leave a short stubble, which reduces total yield. For this reason, many growers prefer hand-cutting when the aim is high-quality bagged silage.

3) Chopping & preparation

After cutting, the crop moves quickly to the chopping unit. The machine chops the whole plant into fine pieces and often splits kernels to improve digestion. Then the chopped material is blown into tractor trollies and moved to packing. Additionally, we inspect random samples for milk line and kernel abundance to confirm ideal harvest timing.

4) Moisture controlled & Innoculant sprayed

While most decisions are made by experience, we target a moisture range of roughly 60–65% for bagged silage when we take measurements.

We always use handheld moisture meters and pH meters to ensure consistency; pH checks confirm good fermentation conditions.

We apply silage inoculants (brand names kept internal). We do not mix molasses, urea, or other additives in routine batches — pure corn silage is generally adequate when crop abundance is high.

5) Bagging, vacuum sealing & secondary protection

We pack silage into 40–50 kg vacuum-sealed inner bags made from thick, airtight plastic to preserve fermentation.

Each inner bag is then placed inside a heavy-duty PP outer bag for puncture protection and longer storage life. This double-layer approach prevents spillage and extends field durability.

Bags are weighed, labelled and staged for short-term monitoring.

6) Curing, monitoring & dispatch

Bags are kept on-site for 3–4 days to allow initial pressure release and seal settling; we ensure vacuum integrity after this period.

We perform visual checks and temperature/pressure spot checks before loading.

Typical minimum order is ~12 tonnes; lead times vary by season and demand. We deliver nationwide.

Quality control & testing

-

On-site tests: moisture meter, pH meter, temperature spot checks.

-

Lab testing: for large single-lot purchases we take random samples and send them to Soil and “Water Testing Laboratory for Research, Jhang” for nutrient analysis (NIR / crude protein etc.). Lab testing is used selectively for big lots and to reassure large buyers.

-

Record keeping: harvest date, chop settings, inoculant batch and pack weight are recorded for traceability. Because we vacuum-seal and dispatch quickly, our sealed bags maintain quality and often improve with proper storage.

Packaging & handling details

| Item | Detail |

|---|---|

| Bag sizes | 40–50 kg vacuum-sealed inner bag + heavy PP outer bag |

| Target moisture (measured) | ~60–65% (experience-driven; measured when needed) |

| Chop style | Very fine — kernels commonly split for easy digestion |

| Storage monitoring | 3–4 days on-site for seal settling; longer storage possible if kept covered |

| Minimum order | ~12 tonnes (variable with season) |

| Delivery | Nationwide |

| Additives | Inoculants used as needed (brand internal); no routine molasses/urea mixing |

| Certifications | None currently — QA is internal and documented |

Handling & feeding advice

Open bags only when you are ready to feed; after opening, use the silage within a short period as freshness declines once exposed to air.

Vacuum-bagged silage is easy to lift with labour and portion — unlike wrapped bales which often require a forklift after unwrapping.

Store bags covered when possible to extend UV life, though the double-bag system is durable for short-to-medium outdoor storage.

Customer support & guarantees

We provide practical feeding advice and support for buyers — from ration tips to loading guidance.

Claims & quality issues: we handle enquiries case-by-case and can provide lab test records for large shipments when requested.

Marketing note: many customers report improved milk yields after switching to our well-preserved corn silage — we state this as customer-reported and results may vary.

FAQ

Q: Do you accept small trial orders?

A: We do not offer small trial orders routinely; new buyers are welcome to contact existing customers for references.Q: Can you deliver nationwide?

A: Yes — we deliver across Pakistan. Transport and lead time depend on destination and current demand.Q: How long can bags be stored?

A: Properly double-bagged silage can be stored for months outdoors, though indoor/covered storage will preserve quality longer. Once opened, consume quickly.

Call to action

-

Ready to order or need a quote?

Contact us at: +92 313 2222527.

Email: info@babalers.com.

(Or use the site CONTACT FORM and request a silage quote — include destination, required tonnage, and preferred delivery window.)

مکئی سلائس — ہم کیا کرتے ہیں اور کیسے

بابر عزیز بیلرز تازہ کٹی ہوئی مکئی کو اعلیٰ معیار کے ویکیوم پیک کورن سلائس میں تبدیل کرتا ہے جو ڈیری اور فٹننگ آپریشنز کے لیے تیار ہوتا ہے۔ ہم خریداری، چاپنگ، نمی اور پی ایچ چیک، انسولیونٹ (ضرورت پر)، ویکیوم بیگنگ اور ترسیل تک ہر مرحلے کو کنٹرول کرتے ہیں — 40–50 کلوگرام بیگز میں یکساں معیار کی فراہمی، پورے ملک میں۔

فوائد (مختصر)

-

kg 40–50 ویکیوم سیلڈ بیگز میں تیار خوراک

-

آسان ہینڈلنگ اور اسٹوریج

-

یکساں غذائیت اور کم ضیاع

-

پورے پاکستان میں ڈیلیوری اور خریدار سپورٹ

-

صارفین کی رپورٹس کے مطابق بہتری (تقریباً 25% تک دودھ کی پیداوار میں اضافہ؛ نتائج مختلف ہو سکتے ہیں)

مختصر عمل (درجہ وار)

-

خریداری اور انٹیک — فصل کو احاطہ میں لے آتے ہیں اور جانچتے ہیں۔

-

کٹائی کی تیاری — رنگ، دودھ لائن اور دانے کی تعداد کی جانچ۔

-

باریک چاپنگ — دانہ تقسیم ہوتا ہے تاکہ ہضم آسان ہو۔

-

نمی اور پی ایچ کنٹرول — نمی میٹر اور پی ایچ میٹر کا استعمال۔

-

بیگنگ اور ویکیوم سیلنگ — اندرونی ویکیوم بیگ + بیرونی پی پی بیگ۔

-

علاج اور ترسیل — 3–4 دن نگرانی، پھر شپمنٹ۔