What is silage?

Silage is fermented, high-moisture forage (maize, grass, sorghum or mixed residues) compacted and sealed to preserve nutrients for animal feed it is abundantly available in Pakistan.

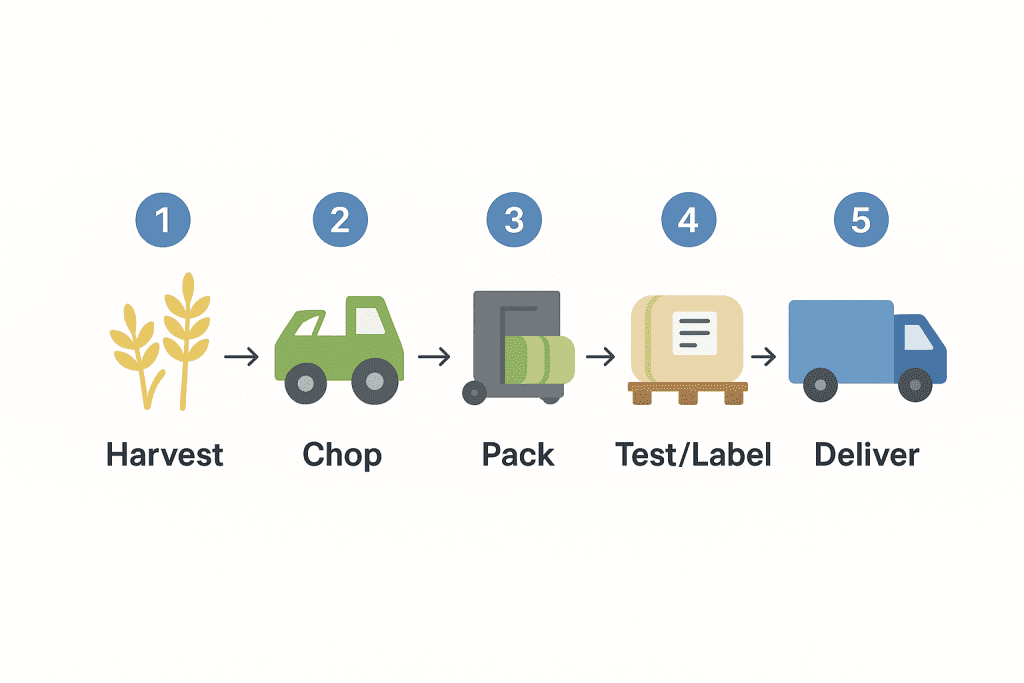

How is silage made?

Crops are cut at peak nutrition, chopped, compacted, and sealed in bags, wrapped bales, or bunkers so they ferment anaerobically and remain stable for months.

What types of crops are used to make silage?

Common feedstocks include maize (corn), sorghum, grasses, and sometimes crop residues like corn cobs and citrus pulp mixed with green forage.

How long does silage last?

Properly sealed silage can keep 6–12 months or longer; opened bags should be used within a few days to avoid spoilage.

Is silage better than wheat straw for milk production?

Yes — silage contains more digestible energy and some protein, so cows fed silage typically produce more milk than those on straw-based rations.

Does silage need extra protein or cake?

Often no — good quality silage can meet much of a cow’s energy needs and reduce or remove the need for extra cake, unlike wheat straw which usually requires protein supplementation.

should I feed per cow per day?

How much silage Amounts vary by cow size and milk targets; small dairy farms often feed 8–12 kg DM (dry matter) of silage per cow per day as part of a balanced ration.

What is the difference between bagged (wrapped) silage and bunker silage?

Bagged (wrapped) silage is made in small sealed units (40–80 kg) that are portable and easy to portion. Bunker silage is stored in large pits and needs heavy equipment and disciplined face management.

What bag sizes are best for small/medium farms?

40–60 kg bags are easiest for manual handling; 80 kg works if you have forklift handling.

Can all animals eat silage?

Yes — silage is suitable for dairy cows, beef cattle, buffalo, sheep and goats when mixed into appropriate rations for each species.

How should I store wrapped silage bales?

Is silage cheaper than wheat straw once transport and nutrition are considered?

Usually yes. Silage has higher energy per kg and lowers the need for expensive cakes, the cost per litre of milk can be lower even if raw price/kg is similar.

How do I calculate cost per litre of milk with silage?

Sum daily feed cost (silage + any concentrates) and divide by litres produced per day. Compare that with straw + cake cost divided by litres produced for a direct comparison.

Can a single operator run a mobile silage line?

Yes — modern portable chopper + wrapper systems are designed so a small crew or a single trained operator can run a mobile silage line.

Do I need special machines to make silage?

You need a chopper and a bagger/wrapper (or small-bale wrapper) to produce bagged silage; mobile services are available if you don’t own machines.

How moist should the crop be when ensiling?

Target 60–65% moisture for maize/grass silage. Too wet or too dry can lead to poor fermentation or spoilage.

How do I check silage quality (what to test)?

Check moisture (%), smell (pleasant ferment, not rotten), pH (low, typically <4.5), absence of visible mold, and lab test for energy and crude protein if available.

What are common silage mistakes to avoid?

Common errors: ensiling too wet or too dry, poor compaction, punctured plastic, opening large faces in bunkers,not using properly chopped corn and not testing moisture/pH.

Can bad silage make animals sick?

Yes — moldy or poorly fermented silage can cause reduced appetite, diarrhea, and in severe cases toxin-related illness. Always reject visibly moldy feed.

Can silage be exported or containerized?

Yes — small wrapped bales and palletised bagged silage can be loaded into containers for longer transport and export.

How soon can I get silage from a supplier like Babar Aziz Balers?

Lead times vary by stock and location; contact Babar Aziz Balers for current availability — many orders can be fulfilled within days if stock and transport are available.

Why is silage becoming popular in Pakistan now?

Because of rising straw costs, better local machinery, improved supply chains, and the clear nutritional and handling advantages of packed silage.

Which regions in Pakistan can grow good silage crops?

Can crop residues (corn cobs, sugar pulp) be used for silage?

Yes — residues can be mixed with green forage or additives and ensiled successfully, improving feed value and reducing waste.

How moist should the crop be when ensiling?

Target 60–65% moisture for maize/grass silage. Too wet or too dry can lead to poor fermentation or spoilage.

Who should I contact to order packed silage from Babar Aziz Balers?

Contact info@babalers.com or call 0313-2222527 for quotes, samples and delivery schedules.

To find out about Babar Aziz Balers silage making process, price and other details CLICK HERE