Introduction

Pakistan’s livestock sector is huge and growing—but it faces a chronic feed shortage. Traditional green fodder and crop residues cover only part of demand, leaving large energy and protein gaps for animals. Silage — fermented, moisture-controlled fodder made from maize, grass, sorghum or mixed residues — is rapidly emerging as the practical, affordable solution. It preserves nutrients, reduces wastage, stabilizes costs, and delivers better animal performance. This post explains what silage is, why it’s better than traditional fodder, how it cuts costs in Pakistan, and why adoption is accelerating across the country.

What is silage and how is it made?

Silage is fresh green forage (maize, sorghum, grass, or crop residues) cut at peak nutritional value, compacted, and sealed in an oxygen-free environment so it ferments. That controlled fermentation preserves sugars and proteins and produces a palatable, energy-dense feed that can be stored for months. Silage can be made on-farm (low cost) or at processing units (small bales, big bales, or chopped silage packed for transport).

Silage vs. Traditional fodder — the practical and nutritional edge

Better nutrition per bite

-

Silage is richer in digestible energy (starch & sugars) than dry straw or poor hay.

-

Farms switching to maize/grass silage commonly report 15–20% higher milk yields and faster weight gain in beef cattle compared with diets based on straw/hay and low-quality roughage.

Less nutrient loss, less spoilage

-

Hay must be bone-dry and is vulnerable to rain, shattering and UV loss. Silage is harvested and sealed immediately, locking in vitamins and sugars that would otherwise be lost.

-

Properly packed silage has much lower feeding and harvest losses than open-stored fodder.

-

Silage lets farmers capture surplus green forage in the growing season and feed it through the lean months (winter/drought). A 90–100 day maize crop can feed a herd for many months when ensiled correctly—solving seasonal shortages and avoiding panic buying.

Dairy and cattle farming made doable for low-income farmers

Before silage became common in Pakistan, small farmers had to grow their own pattha (green fodder). They needed extra land, labour to cut it, and time to harvest and feed it every day. This made dairy farming expensive and difficult for anyone with limited income. Silage has changed everything. Now any farmer can simply buy ready-made silage bags, store them for months, and feed their animals whenever needed. Even one or two workers can easily open the bag and feed the herd. This saves time, reduces labour costs, and makes dairy and cattle farming practical for small and medium farmers across Pakistan.

Cost & economics — why silage saves money in Pakistan

-

Feed is the single largest cost on a dairy farm (often up to 70%). Switching to silage reduces feed bills by replacing expensive commercial fodder and concentrates.

-

Local price examples show big savings: on-farm maize silage in some areas can cost PKR 12–16 per kg, while market silage and poor quality hay cost substantially more per unit of usable energy. Online marketplace prices and regional reports indicate corn silage averages roughly PKR 10–13k per tonne (≈PKR 10–13/kg), with wide regional variation.

-

Research and extension trials in Pakistan have demonstrated 25–30% reductions in feed cost when silage (or silage-based mixes such as corn cobs + other residues) replaces pricier components.

-

Lower waste and steady supply also protect margins by avoiding seasonal price spikes.

Real animal benefits (milk, meat and animal health)

-

Higher milk yield and stability: Farmers using maize silage often report stable, higher yields through winter. Typical increases are in the 15–20% range.

-

Better growth for beef animals: Silage-rich rations improve daily weight gains and slaughter weights.

-

Reduced need for concentrates: Because silage supplies both energy and fermentable fiber, farms often cut back on expensive concentrate mixes.

-

Health improvements: Balanced silage rations lower metabolic stress and support immunity; the palatability of silage also reduces sorting and selective feeding.

Adoption & market trends in Pakistan

-

Awareness campaigns, NGO programs and government extension (NARC, PARC and international projects) have helped spread silage know-how.

-

Programs such as the Market Development Facility (MDF) and private processors promoted small-bale silage, and thousands of households and small farmers adopted silage practices in project areas.

-

Urban milk demand (most of Pakistan’s milk is sold in cities) is driving processors and large farms to secure year-round, high-quality feed—silage fits that need.

-

Entrepreneurs are finding silage profitable: small processing units can be lucrative, with attractive IRR in feasibility studies for silage processing businesses.

Practical models for Pakistan: small-bale & bulk silage

-

On-farm silage (low-cost): Farmers with maize or sorghum crops ensile in pits or wrapped bales for their own herd — best for savings and self-sufficiency.

-

Small-bale silage (commercial): Small, wrapped bales (60–80 kg) are ideal for smallholders or dairy cooperatives—easy to handle and transport.

-

Bulk silage / processed chopped silage: For feed mills and large farms, chopped and packed silage or silage pellets let buyers buy to specification and reduce handling.

Barriers & challenges — and how they are being solved

-

Lack of awareness and training: Still common in many rural areas; extension services and demonstration plots help.

-

Machinery access: Choppers, balers and wrappers require investment. Solutions: mobile service providers, rental machinery, micro-finance and bank loans for small processors.

-

Quality control: Improper packing causes spoilage. Training and simple QC (moisture testing, clean chopping, sealing) fix most issues.

-

Supply chain logistics: Moving silage is heavier than concentrates—so local sourcing and processing are best. Containerized small bales and palletized packing are working solutions for longer-haul sales and exports.

Case highlights & evidence from Pakistan

-

Extension trials and farmer reports show marked increases in milk yields where silage replaced poor fodder. Some project areas reported doubling of milk in winter on silage diets.

-

Local price comparisons from project regions show silage can cost half of commercially purchased fodder on a per-kg-nutrient basis when produced on-farm or locally processed.

-

Development projects and research institutions (NARC/PARC, MDF) are actively promoting silage production and small-bale supply chains to reach smallholders.

How farmers and feed mills can start (practical steps)

-

Identify feedstock: maize, sorghum, grasses or crop residues (corn cobs, citrus pulp, sugar pulp) are suitable.

-

Harvest timing: cut at optimal maturity for highest sugars (maize at dough stage).

-

Chop & compact: chop to recommended length and compact to remove oxygen.

-

Seal & monitor: wrap or pit-seal; monitor fermentation (smell, colour).

-

Test and formulate: get simple proximate tests (moisture, crude protein) and blend into rations.

-

Consider mobile services: if you don’t own machinery, hire mobile chopping/wrapping services or partner with local silage processors.

FAQs

Q: What is the difference between silage and hay?

A: Hay is dried forage stored dry; silage is moist forage fermented in anaerobic conditions. Silage retains more nutrients and is less weather-sensitive.

Q: Can crop residues be used for silage?

A: Yes — corn cobs, citrus pulp, sugar pulp and even straw mixed with green forage can be ensiled successfully with the right additives/technique.

Q: How much does silage cost in Pakistan?

A: Prices vary by region and quality. Market reports show roughly PKR 15–20/kg for commercial corn silage (approx.), while on-farm production can cost PKR 20–25/kg in some areas — often cheaper per unit of energy than hay or concentrates.

Q: Will silage really increase milk?

A: Yes — balanced silage diets commonly raise milk yield by 15–20% and stabilize production in lean months.

Conclusion — why silage is the future

Silage tackles Pakistan’s two biggest livestock problems at once: feed quality and seasonal availability. It preserves nutrients, cuts waste and cost, and supports higher productivity. With rising urban milk demand, growing technical support from research institutions and profitable business models for processors, silage is transitioning from pilot projects into mainstream practice across Pakistan. For farmers, feed mills and entrepreneurs, silage is no longer experimental — it’s the feed solution for the next decade.

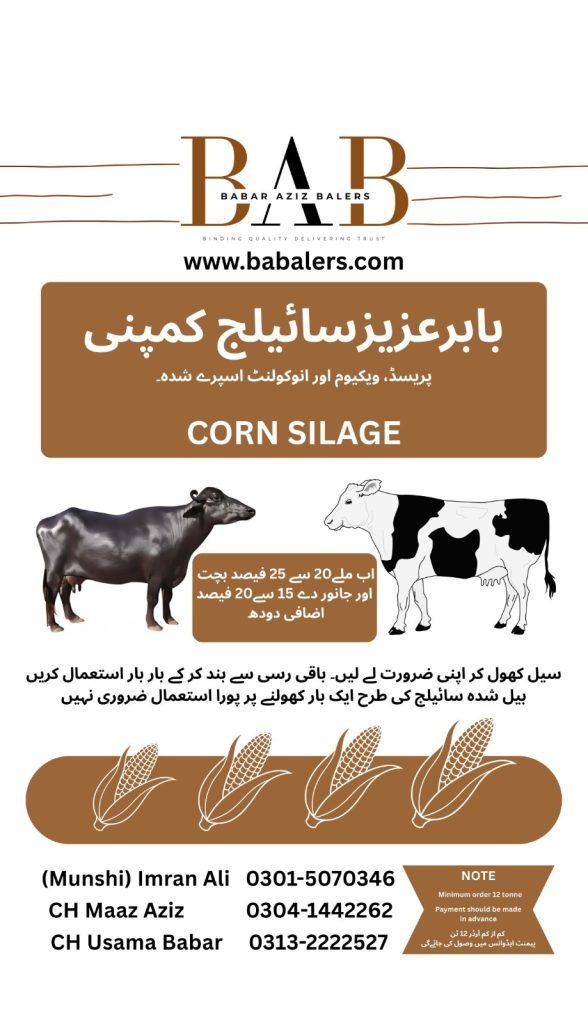

About Babar Aziz Balers — our new silage service

At Babar Aziz Balers we’ve started packed silage production alongside our established wheat straw, sesame straw and chopped biomass services. We can supply small wrapped bales or bulk chopped silage, moisture-tested and packed for safe transport. If you’re a dairy farmer, feed mill or miller looking for reliable, high-quality silage, contact us:

We have 50 kg bags of silage always ready for dispatch

Note: minimum order is 50 tonne and payment should be made in advance

📞 0313-2222527

✉️ info@babalers.com

www.babalers.com

To find out about Babar Aziz Balers silage making process, price and other details CLICK HERE