Introduction

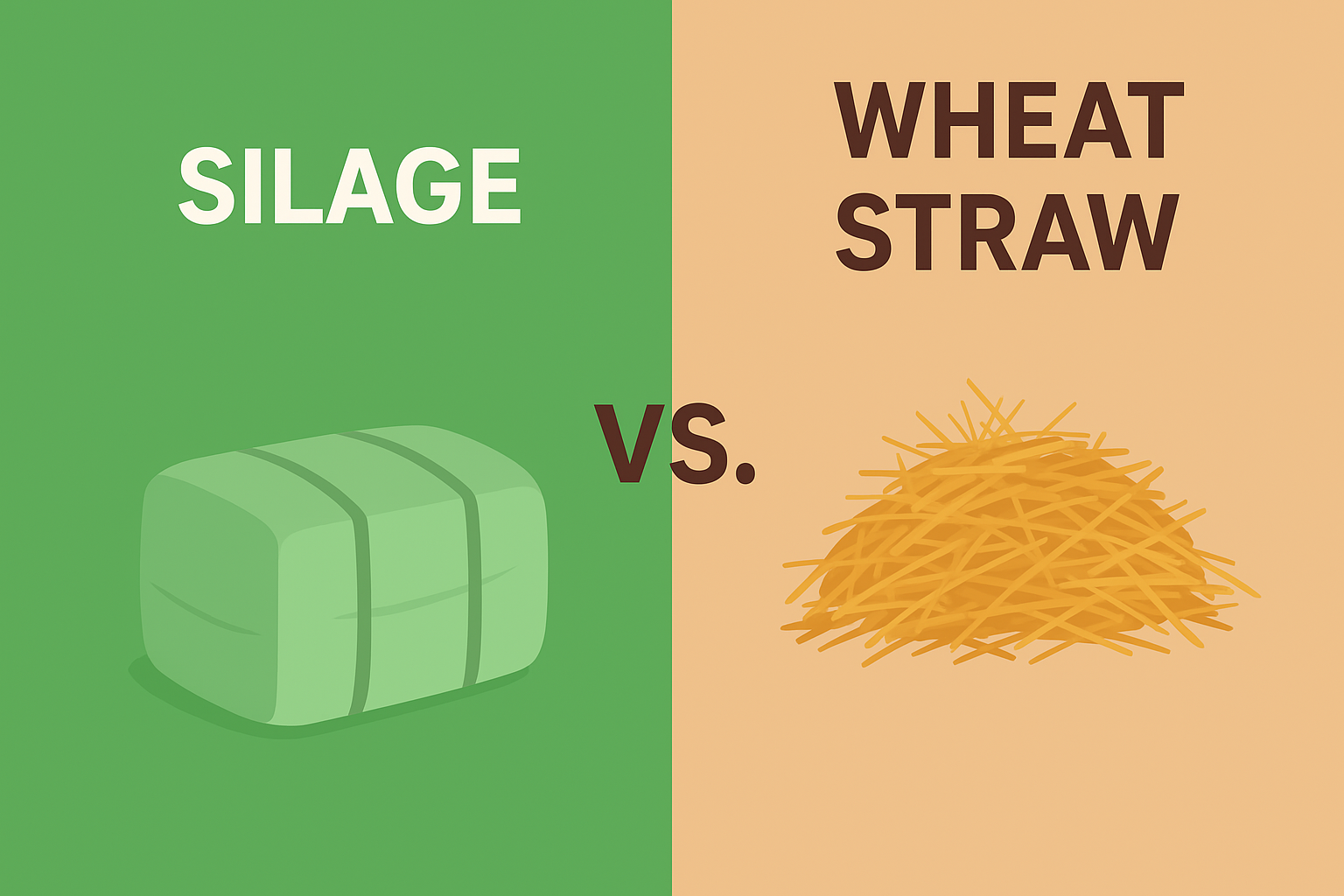

For decades wheat straw was the default cheap feed and biomass in Pakistan. Today that advantage is disappearing. Rising production and transport costs, seasonal shortages, the low nutritional value of straw (which must be heavily supplemented), and the availability of fast, locally made silage machinery are combining to make silage the smarter choice for dairies, feed mills and forward-thinking balers.

Below I explain the economics, nutrition, logistics and practical steps — using real on-the-ground figures and experience from our operations — so wheat-straw businesses can pivot profitably.

1) Real prices: what farmers and traders are paying today

Silage (packed, market): roughly PKR 16–24 per kg (varies by region and packing).

Wheat straw (baled): roughly PKR 15–25 per kg, heavily dependent on colour, dust content, moisture and season.

Note: those ranges overlap on paper, but they don’t tell the whole story — silage delivers far more usable nutrition per kg, so cost-per-effective-feed is usually lower for silage.

2) Nutrition: the decisive advantage of silage

Wheat straw is very low in digestible energy and protein. To match milk yields achieved with silage, straw-based rations must be supplemented with protein sources (cottonseed cake, soybean cake etc.), adding to total cost.

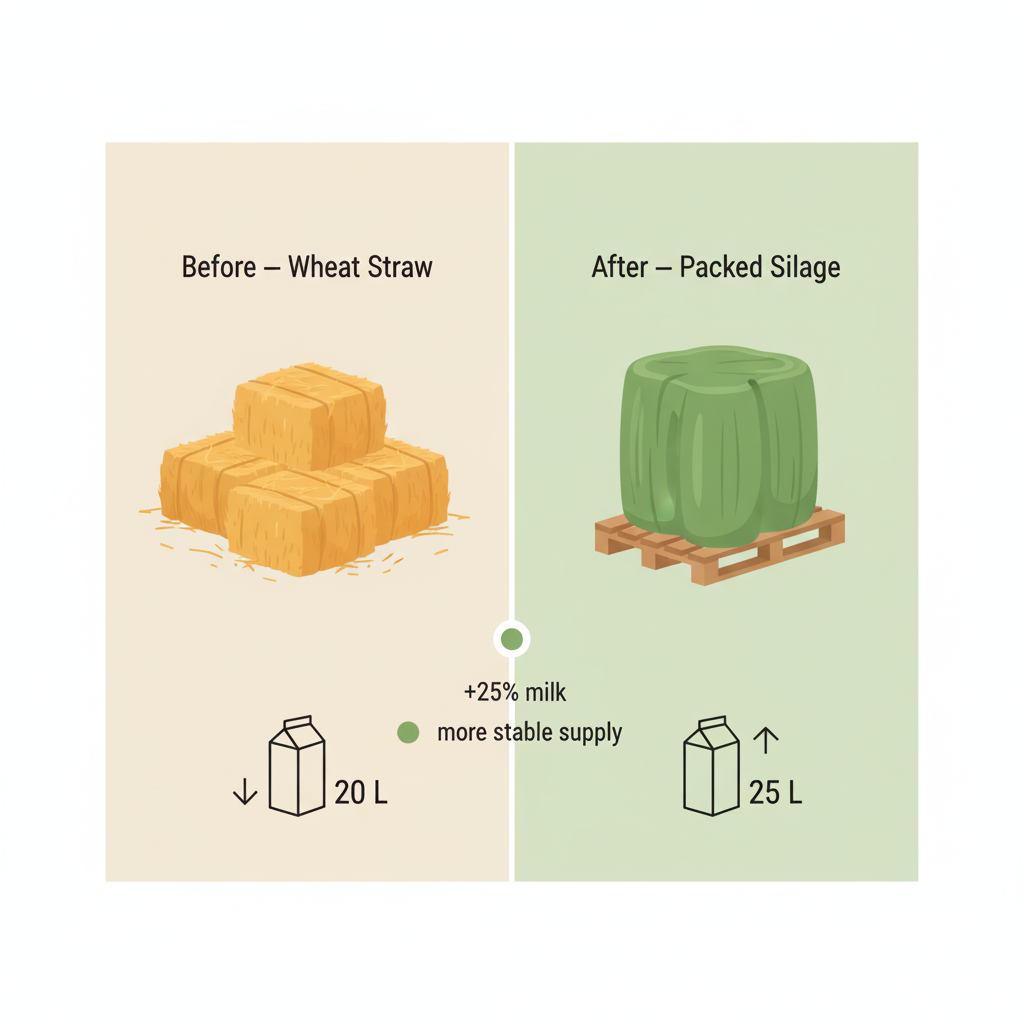

Silage contains natural fermentable energy and some protein, so it often reduces or eliminates the need for extra cake in the ration. In our real customer experience and trials, switching to silage produced roughly 25% higher milk yield compared with the same herd on straw + standard supplementation. That yield bump outweighs small per-kg price differences.

- Practical takeaway: don’t compare price/kg — compare price per litre of milk produced. In most supply routes that favours silage

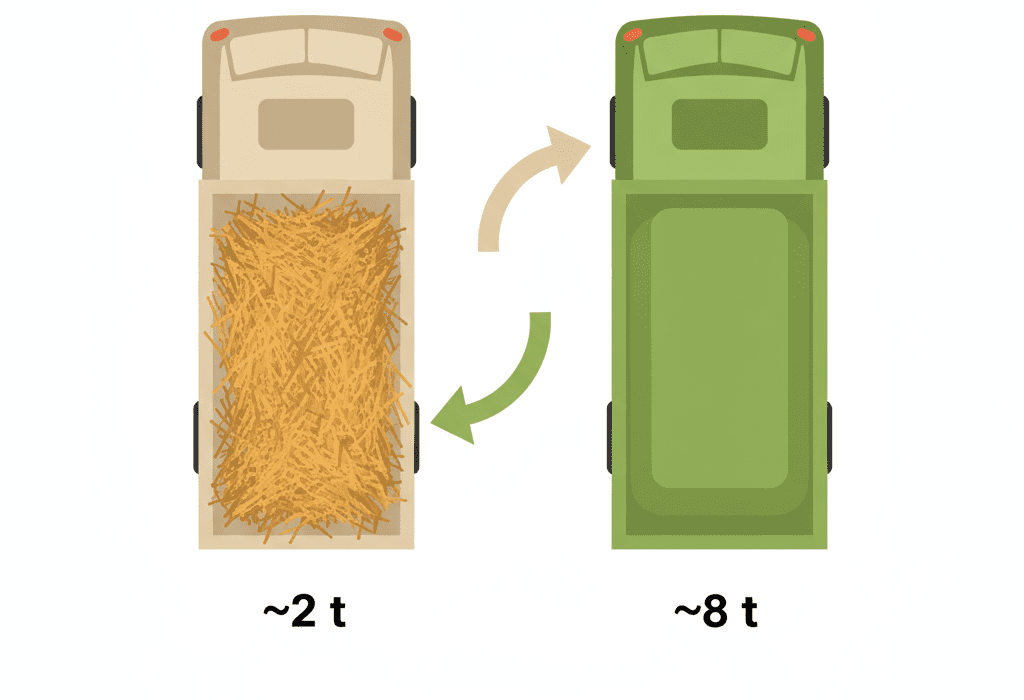

3) Transport & handling: density wins

Silage is chopped, compacted and wrapped — much higher weight per truckload than bulky wheat-straw bales. That reduces the number of trips and the per-tonne transport cost.

Wheat straw’s low weight-to-volume ratio forces either many trips or illegal overloading to be economical. With stricter enforcement and rising fuel costs, overloading is no longer a viable solution: fines + delays kill margins.

- Practical effect: even when silage and straw prices look similar at origination, delivered cost and usable energy almost always favour silage on medium- and long-haul routes.

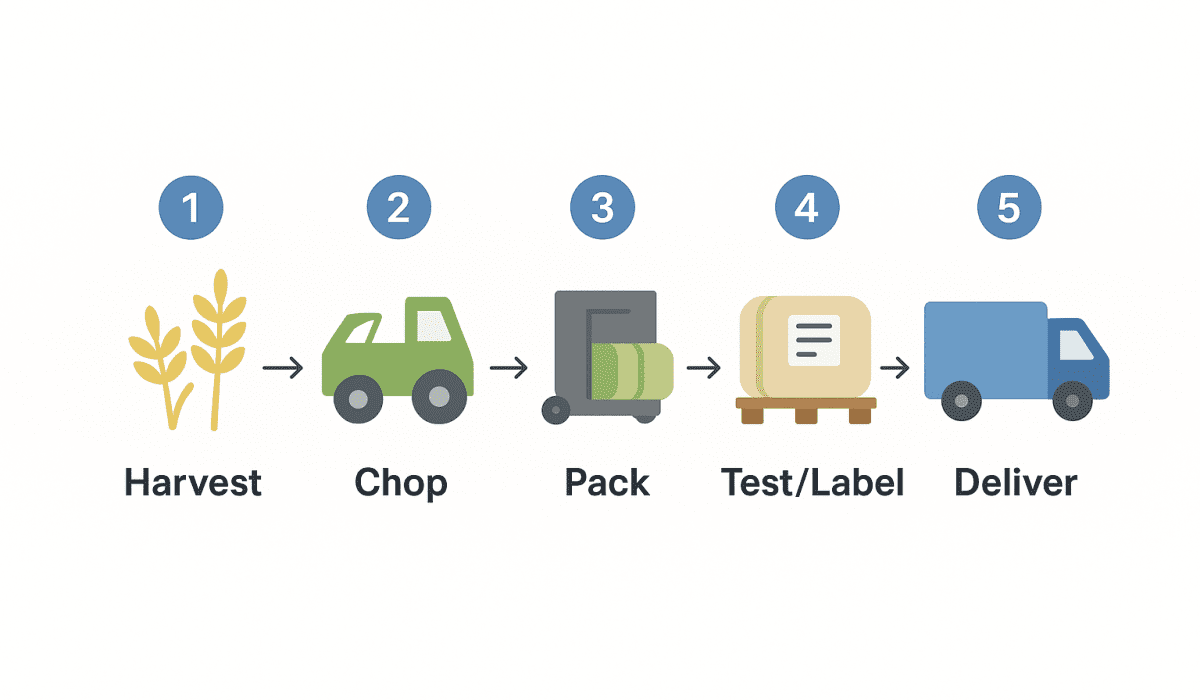

4) Mechanisation: one person can now run a silage line

The game changed when mobile choppers, baggers and wrappers became affordable and parts were made locally. We use custom machinery built for Pakistani conditions — high-speed, repairable with parts available locally.

Result: a single small team (or even one trained operator with mobile equipment) can produce and pack silage on rented land or at a baling centre. That turned silage from “specialist” into scalable, repeatable business.

- At our Jhang center we’ve already shifted fully to silage; Kacha Khu will follow soon. We run a fixed silage service at the moment with bag sizes of 40–60 kg — easy for two people to handle.

5) Year-round supply and lower spoilage risk

Wheat straw prices spike in winter when supply tightens; many buyers report straw becoming unaffordable by December–February.

Silage, produced at peak green growth and stored anaerobically, offers predictable, year-round supply. Properly sealed bags/ wrapped bales have low spoilage compared with repeatedly opened straw stacks or open loads that get musty.

- For dairy processors and commercial farms that cannot tolerate seasonal feed shocks, silage is a far more reliable contract commodit

6) Business reasons balers are switching today

Margins: Straw margins have tightened as production, handling and transport costs rose. Silage opens new margins: higher-value, repeat contracts with dairies and feedmills.

New customers: Dairies, co-ops and processed-feed companies prefer a consistent, testable product — silage fits better than variable straw.

Service opportunities: Mobile silage services, bagging contracts, and pre-packed product lines create recurring revenue that straw trading doesn’t.

- Regulatory environment: With stricter axle/weight enforcement, compact feed transport (silage) is easier and less risky.

7) Practical comparison (quick table)

Factor Wheat Straw (baled) Packed Silage (bag/wrapped) Market price (typical/kg) PKR 15–25 (quality dependent) PKR 16–24 Usable nutrition per kg Low — needs cake Higher — less cake needed Transport efficiency Poor (bulky) High (dense) Handling Heavy manual stacking, overloading risk 40–60 kg bags, stackable, palletisable Spoilage once opened High (exposed) Low (open 1 bag at a time) Machinery requirement Press & baler Chopper + bagger/wrapper (mobile) Best customer Local short-haul, biomass buyers Dairies, feedmills, medium/long haul buyers

8) Extra operational points

Traceability & quality testing: Bagged silage can be labelled with date, moisture and crop ID — buyers trust tested batches more than a bulk straw load that varies by colour and dust.

Service revenue model: Balers can add mobile chopping/wrapping as a billed service to farmers (platform for recurring income).

Stackability & export: Small wrapped bags fit in containers and pallets for longer logistics — straw is hard to containerise economically.

Waste & environmental angle: Using storable silage reduces open-field burning of residues and is eco-friendly messaging you can sell on.

9) Risks & how to manage them

Initial capex for choppers/wrappers — mitigate with rental, shared ownership, or contract mobile services.

Skill & QC: Ensure operators monitor moisture and chop length; poor technique spoils silage. Training pays for itself.

Plastic waste: Plan bag/film collection and recycling or a take-back system. Offer lower-cost reusable palettes or partner with recycling agents.

Market education: Some traditional farmers still distrust silage; demo cows, sample packs and small-sale pilots win converts.

10) Clear next steps for wheat-straw balers & traders

Pilot silage at one center (you already have Jhang — scale gradually).

Offer 40–60 kg packed bag sizes — these hit the sweet spot for labour and transport.

Sell total landed cost comparisons to your buyers (show them straw+cake vs silage per litre of milk).

Provide mobile service packages (harvest → chop → wrap → deliver).

Train a small team on moisture %, chop length and sealing — quality is your brand.

Bundle logistics (deliver price including transport) so buyers don’t compare only ex-yard prices.

Keep some straw business for biomass buyers who still need it — but price and margins will dictate volumes.

Case snapshot — our results (what we’re seeing)

Centers: Jhang shifted to silage; Kacha Khu moving soon. We run a fixed silage line; bag sizes are 40–60 kg.

Yield uplift: Customers report ~25% increase in milk yield after switching from straw-based rations to silage (our on-field experience and customer feedback).

Price example: Silage market ~PKR 16–24/kg; straw ~PKR 15–25/kg (quality-dependent). Even when per-kg numbers overlap, silage wins on delivered usable feed and handling.

Conclusion

The market is changing fast. Wheat straw’s old advantages are being eroded by higher handling and transport costs, quality inconsistency, and the need for costly supplementation. Silage — compact, nutritious, transport-efficient and now producible with locally maintainable machinery — is becoming the feed of choice for dairies and feedmills across Pakistan. Balers who adapt (mobile/fixed silage lines, 40–60 kg bags, logistics bundles) will capture new revenue streams and stronger, repeat customers

Contact / Pre-order

Babar Aziz Balers — Fixed Silage Service & Packed Silage

📞 0313-2222527 | ✉️ info@babalers.com | www.babalers.com

To find out about Babar Aziz Balers silage making process, price and other details CLICK HERE